←Return

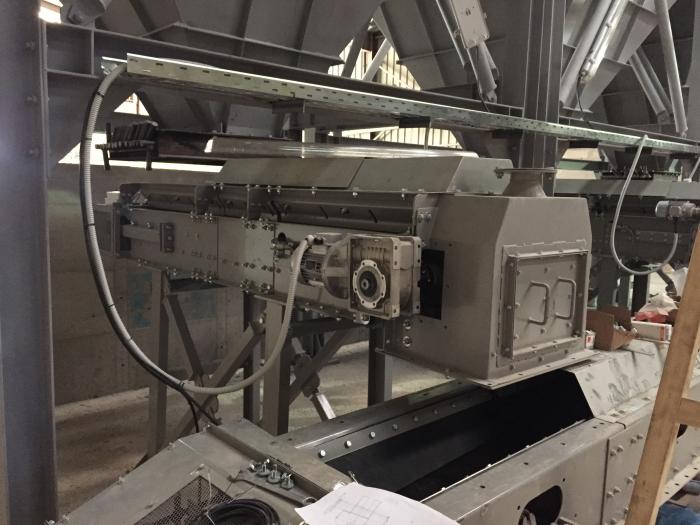

This type of Belt Conveyor is generally used in heavy duty applications (quarry, mine, clinker etc.) when we need to feed the material in the production line in a predefined and totally adjustable set point. The weighing system with maximum 0, 5 % deviation helps the user to know the exact productivity of the production line or even can recipe a material mix in a precise and absolute way. Usual cases are below hoppers, silos and other intermediate stocking equipment. There are lots of accessories that accompanies the Weighing Belt Conveyor such as covers, dust sealing, self-alignment troughing sets, great variety of weighing systems, machined rollers for perfect weighing conditions, automatic tension devices, impact bars or impact rollers, several cleaning and pre cleaning systems, safety sensors (pull rope switches, speed sensor, belt misalignment sensors, outlet hopper choke and level sensors), lots of choices in driving systems ( Helical bevel Gear Reducer with Hydraulic Coupling , Parallel shaft Gear Reducer with Taper Lock etc.), Rock Box Feed Chute or Plain Feed Chute, Outlet Hopper Rock Box type or Plain, Lining in inlet or outlet hopper, Special Rubber Skirting Systems in total length of the conveyor and plenty more. Also the Weighing Belt Conveyor may be delivered in Stainless Steel, Hot Deep Galvanised Steel, and Sand Blasted Steel Structure with all the types of painting included in our variety.